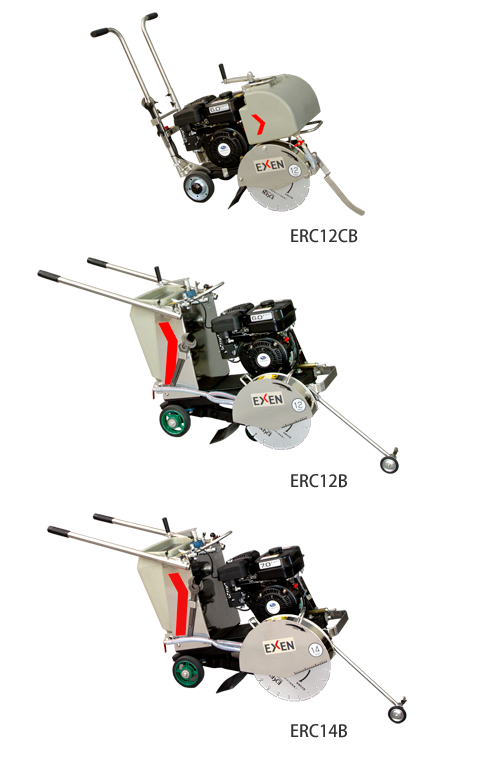

This Exen hand-pushed concrete saw emphasizes cutting performance, durability, rustproofness, and safety. The ECR12CB chassis is made of aluminum. With the chassis of ECR12B to 14B made of ductile aluminum, these products are machined with high precision, high rigidity, and low center of gravity to achieve stable operability and excellent cutting capacity. This concrete cutter achieves particularly high worker safety by being designed to meet adequately the safety requirements for JIS-compliant road works machinery. Also available are optional blades (for asphalt and concrete), diamond blades (P/C series), designed specifically for the ERC series.

Designed to meet adequately the work requirements for road works machinery

Exen concrete cutters, safely designed according to the requirements of the safety standards for JIS-compliant road works machinery, achieve high work safety.

1. An additional engine stop switch at hand

2.The blade case deepened in case of an unexpected accident

3.The belt cover structured not to let a hand or finger in

4.The up/down stopper turned into a lever type to prevent it from interfering with the high-temperature parts of the engine

5.The hooks displayed clearly

6.Equipped with a parking brake

Excellent cutting performance

A body-supporting component and therefore the most important, the chassis is made of cast aluminum (12CB) and ductile cast iron (12B and 14B), with highly precise machining, high rigidity, and low center of gravity, thereby achieving stable operability and cutting performance.

In pursuit of durability and rustproofness

The blade case, belt cover, tank house, handle, and other main components are made of rust-resistant stainless steel (SUS) in pursuit of durability and rustproofness.

Even safer than conventional models

These products each have, as standard equipment, a hand switch that allows you to stop the engine at hand.

For the stop switch in front of the engine, the diamond blade in revolution comes closer to the worker to facilitate engine stoppage.

To combat that problem, the new products come equipped with a stop switch at hand, in addition to the one installed in conventional models.

Among other additional features is a belt cover designed not to allow your hand to enter, resulting in even higher safety.

Equipped with a large-capacity water tank (with a punch plate)

These products come equipped with a large-capacity polypropylene tank of the largest order of its class, robust and durable, which cannot gather rust and allows disconnection without keeping a hose attached from outside at all times.

The punch plate can serve as a filter for use in case accumulated water is used.

Also available is a hose insertion port, which facilitates water supply (for all models).

Water residues can be easily disposed of through a drain valve, which is installed as standard equipment (except for 12 CB).

Equipped with a 3VX

All models come equipped with a low-edge cog type 3VX belt.

The cogged belt reduces the incidence of belt breaks and revolution losses.

These cutters are also designed with higher safety by a safe structure that prevents your hand from going behind the belt cover.

Blade attachment made easy

The blade case is so structured as to be installed in a single touch, which facilitates blade attachment (12B to 18DSB). The ERC12CB is so structured as to allow the blade case side to open.

Note: Numbers indicated as part of each concrete cutter model name are expressed in inches for the largest diamond blades.

(Example: ERC12CB means that it accommodates 12-inch parts; ERC16DCB means that it accommodates 16-inch parts)

Exen concrete cutters are standardized at a diamond blade shaft hole diameter of 27 mm for all models.

Higher cooling efficiency with centrifugal water injection into the blade

The blade holder is of the centrifugally dispersion type that allows cooling water to reach all corners of the blade by centrifugal force. This increases cooling effect, along with cutting performance and blade life (except for the 12CB).

Engine throttle lever as standard equipment

Available as standard equipment is a throttle lever with which to adjust engine revolution at hand (except for the 12CB).

.png)